grounds

Autumn 2023

Timeline: 10 weeks

Collaborators: Cole Young

Industry Sponsor: Anvil Studios (Seattle)

SolidWorks + Rhinoceros 3D + Keyshot + physical prototyping + Adobe Suite + Prusa 3D printing + Figma interface prototyping

A system that repurposes spent coffee grounds from local coffee shops into planter pods.

Grounds focuses on encouraging users to compost and addresses the increase in landfills from coffee consumption.

VIDEO ANIMATION

Check out the design process behind

↓

In addition to our academic research, we also conducted interviews with relevant stakeholders and used this information to make better decisions about the scope of our project and the direction we intended to move in.

While these interviewees did not necessarily represent a fully diverse spectrum of the potential stakeholders for our design, we felt that they adequately addressed the important areas of concern that we were looking to research in this step.

USER INTERVIEWS

-

A former barista who worked at Starbucks for 1.5 years and a small independently owned coffee shop for 2 months. Some insights:

An extremely busy coffee shop during peak business hours can produce roughly two large trays of spent coffee grounds per hour.

Many people don’t know that places like Starbucks give away grounds (although not every location participates in this program).

Many places don’t give away grounds and throw them away.

-

A college student who frequents coffee shops in addition to regularly making coffee at home. Based on her interview, we found that:

A regular at-home coffee drinker produces about 5 tablespoons of spent ground waste per serving of coffee.

Other wastes that she produces are discarded into landfill (Keurig pods, coffee liners, instant coffee packets) or recycled (Nespresso pods, syrup glasses).

-

A barista at a smaller chain coffee shop. Some things that stood out to us:

At a smaller/less busy cafe, it may be closer to one tray every 2+ hours.

Baristas don’t always get the chance to clean out machines of ground to compost or give them away.

Customers rarely come into coffee shops and ask to take spent coffee grounds.

-

A frustrated roommate who hates dealing with compost. She notes that:

Composting is seen as a hassle and messy, especially with things like bags ripping due to moisture and bad odors for at-home compost bins.

Putting coffee grounds and other compostable waste in the trash/landfill is seen as easier due to non-compostable trash bags being more reliable and typically better at containing odors.

KEY FINDINGS

Pain Points and Insights

OVERABUNDANCE OF SCG’s

Coffee shops and at-home coffee drinkers create huge amounts of SCG waste, ~60 million tons per year, with most being sent to landfills.

COMPOSTING IS GROSS!

People are discouraged from composting and generally using spent coffee grounds for anything because the process is messy and inconvenient, making it more likely for SCG to go to landfills.

BENEFITS ARE HARD TO SEE/ NONEXISTENT

We can’t see where coffee shop compost goes or what it does. While some places give away SCG for fertilizer, what happens to SCG that isn’t given away? Ultimately most go to the landfill.

Users want to compost their coffee grounds because it gets rid of waste and promotes sustainable/eco-friendly practices. But composting can be inconvenient, so they need a composting solution that makes the collection and repurposing of SCGs easier.

DESIGN PRINCIPLES

Our Goals and Criteria

SUSTAINABLE WASTE REDUCTION

Create a product that promotes the reduction of SCG waste while also utilizing sustainable product design practices.

CONVENIENT & EASY TO USE

Promote composting by creating a product that is easy to use and reduces the mess & undesirable parts of compost.

ENCOURAGING & UPLIFTING

Create a product that encourages users to repurpose SCG and also highlights positive benefits in an uplifting way that users can track or visualize.

Our initial ideation was centered around composting and took various forms through either a coffee shop installation/machine or an at-home composter specializing in processing coffee grounds.

Our designs would take drastic changes from many of these forms, however, there were some strong elements we liked that were taken forward into the next stages.

INITIAL IDEATION

Some important elements we liked and wanted to revisit in future iterations were:

Integrated and non-intrusive digital interfaces

An encouraging display of waste reduction

Automated processing of coffee grounds

Inviting form factors that fit in with the aesthetics of coffee shops

A “deliverable” form/package of grounds that users can take

SECOND ROUND IDEATION

COFFEE SHOP GRINDER INSTALLATION

A coffee grinder inspired installation placed in coffee shops to allow customers to visualize the amount of SCGs produced by coffee consumption.

+

+

-

Ability to visualize the grounds being processed.

Interactivity and the presence of the installation would be engaging.

Could be impractical and not particularly informative to users.

HOME COMPOST/PLANTER

Using sensors to track users’ waste reduction, its data encourages users to continue to compost SCGs and utilize the resulting fertilizer to garden in the planter.

+

+

-

Interface & encouragement of tracking waste reduction data.

Direct connection to plants/the benefits of composting SCGs is compelling.

Niche product for someone to have in their home/yard; most people would already know about composting coffee grounds too.

PLANTER COFFEE SHOP INSTALLATION

A mix of the previous two concepts, this system would take discarded SCGs and process them to be used directly as fertilizer or be packaged and taken home by coffee shop customers interacting with the product.

Some considerations we moved forward with:

What would it look like for customers to take home spent grounds in a form other than bags of SCG fertilizer?

What are the mechanical processes/parts that need to fit in this product?

How could this product benefit from a digital interface or added experiences?

Our third round of ideation settled on the idea of creating a coffee shop installation that focused on encouraging users to use spent coffee grounds to grow their gardens and improve their communities.

THIRD ROUND IDEATION

A more refined list of features we wanted to include in our final design:

A digital interface on the product to track data about waste reduction

Mixing and molding components to make a planter cup that customers can take and use to grow plants in their gardens & communities

A connected app to help follow up with customers about repurposing spent coffee grounds and encouraging them to keep growing produce and plants

Space for a large amount of spent grounds to be stored to provide for the machine and to help baristas keep up with the SCGs being produced

Clear plastic or glass cutouts to engage with customers and show them how the grounds are being repurposed

MOODBOARD

KEYWORDS: interactive | inviting | rounded | earthy | clean

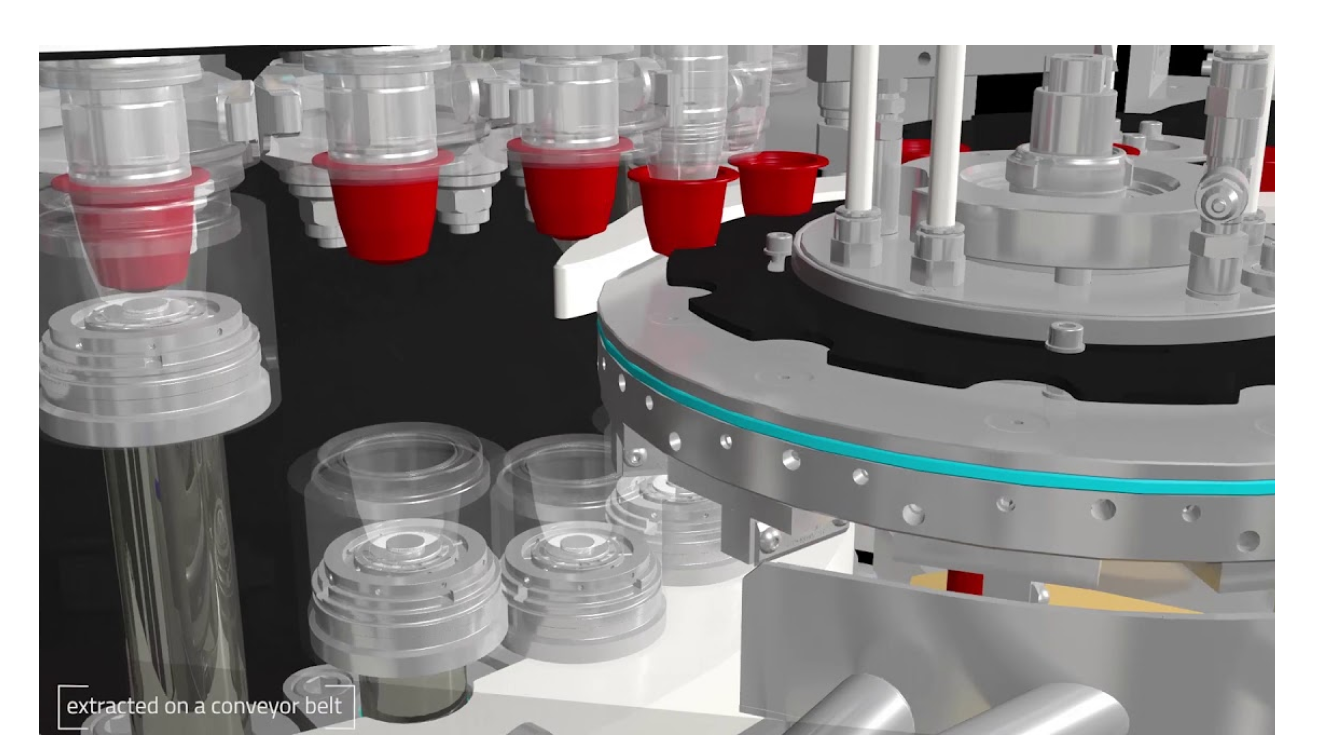

THE MACHINE

Mechanics & Necessary Components

Before moving in to further form iterations, we did more research and finalized the mechanical components and processes, allowing us to feel confident in making informed decisions about how the product would function and what form languages would be appropriate.

-

A heavy-duty mixer in a stainless steel assembly, ensuring strength and durability, used when mixing multi-ingredient batches with small percentage of materials and mix time is critical. (YoungInds)

-

A hydraulic rotary press system designed with considerations of higher productivity, rapid and easy maintenance, CONSTANT WEIGHT AND SIZE OF THE PRODUCT, and energy savings. (SACMI)

-

A digitally-controlled 750W dual heater, with quiet and high-efficiency circulating airflow as well as filtered air intake. (Brod&Taylor)

Going into 3D modeling, we focused on having our product tiered: SCGs first funneling down to be mixed with additives, then into the continuous compression molding system. As we developed our CAD, we continued to adopt the rounded form and legs.

We wanted to utilize rounded forms to make the product feel inviting to customers and less industrial and intimidating within the context of the coffee shop.

We worked especially hard on refining the proportions to be most aesthetically pleasing in addition to being functional and practical within the confines of a coffee shop interior. As a result, our product began to gradually become taller rather than wider to take up less space and had distinct layers to reflect the different stages of processing the spent coffee grounds.

CAD ITERATIONS

FINAL DIRECTION

Defining CAD + CMF Considerations

Several orthographic iterations were made to show different placements of windows, how the interface might be bumped out from the main body of the machine, and the symmetry/relationship between elements such as the funnel, cutouts, and interface altogether.

In the end, we decided to make our interface bold in its display of the waste reduction and savings on the top, while the machine’s progress bar would follow a mirrored “L” shape that mimics the path that the SCGs take through the machine.

During our CAD development, we decided to have the interface and SCG cup portion protrude from the machine in order to draw more attention to this area and make its interactions more accessible.

We also considered extending this protruding part of our design to the floor* and eliminating two legs to make the section feel more integrated. However, to maximize the space for the trays and emphasize a more inviting, “furniture” like feeling, we decided to stick with keeping all four legs and ending the protruding portion at the molding section.

Each step of the process is also color-blocked. We wanted the funnels to be partially transparent to show the grounds being used, and then have more colorful sections below it to draw attention to the SCGs being processed. We made the tray section more muted and dark to deter customers from interacting with it, as this section was only meant to be used by coffee shop employees.

*early form version 1 →

FINAL DIRECTION

System Diagram

FINAL DIRECTION

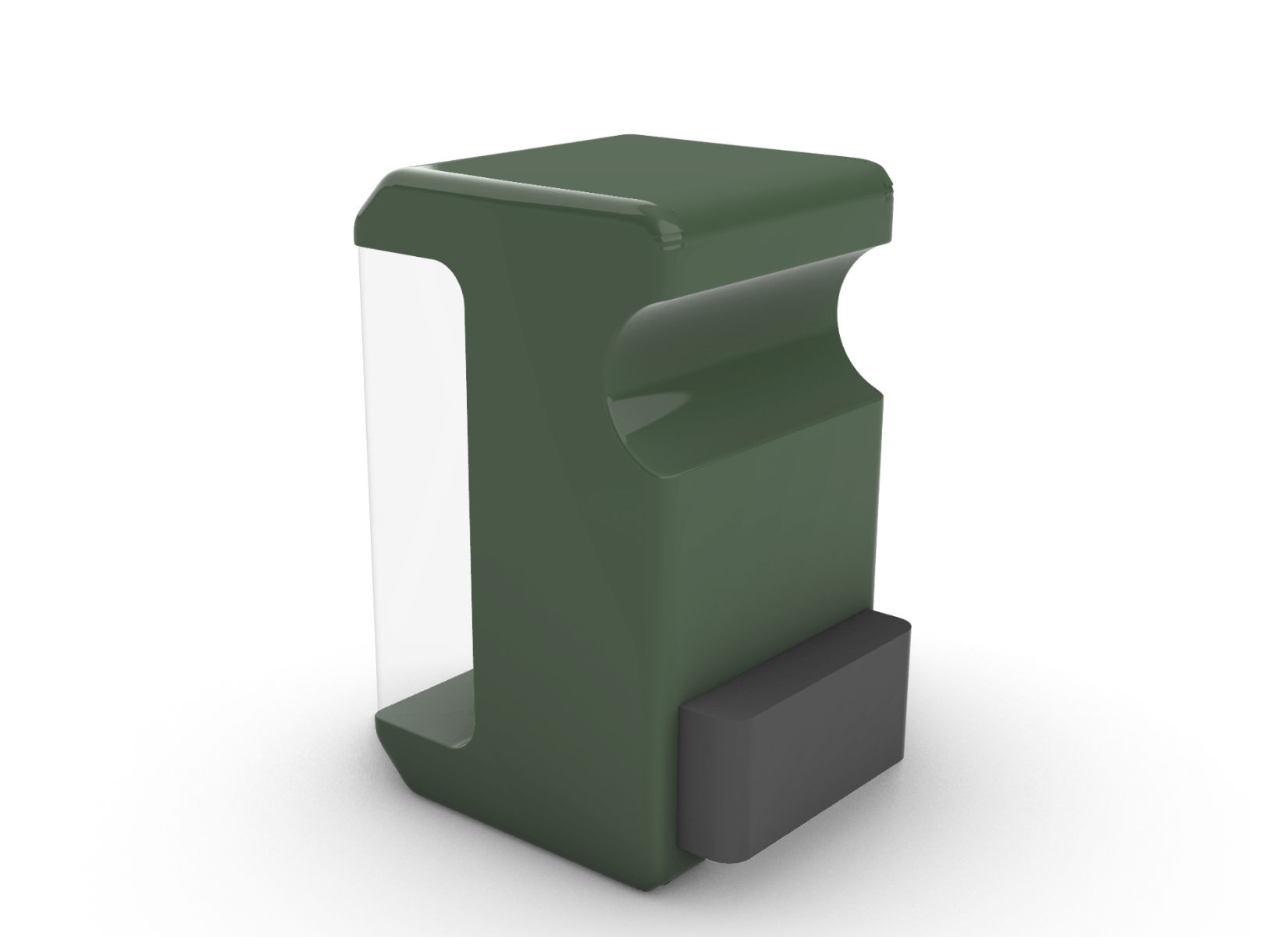

The Pods

We decided to move away from traditional planters or cups and instead create a spent coffee ground “seed pod” that could be easily filled with seeds, put into the ground, and watered. This direction does not require the extra step of needing to get filled with soil, making it more versatile in its usage. Users can put these pods outside in their home gardens, put them in pots inside, or even practice “guerilla gardening” and throw them around their neighborhoods and communities.

3D printed models helped us visualize the size and shape of our pods. We wanted a rounded, seed-inspired form that was easy for users to hold and take home. The pods would be molded/hollowed into two parts: the lid and the cup. These cups would hold seeds chosen by the customers and have a snug-fitting lid to prevent them from opening.

-

Ingredients

50 g of Spent Coffee Grounds (SCGs)

8 g of Carboxymethyl Cellulose (CMC) → a thickener, emulsifier, and viscosity modifier

1.2 g of Xanthan Gum (XG) →a thickening agent

10 g of Cornstarch →an ingredient we found that made our cups more voluminous

100 g of Water

Directions

Bake @ 350° F for 5 min.

Press in mold

Bake for another 5 min.

Air dry to harden

FINAL DIRECTION

UI/UX Wireframe

Creating a rewards system for customers.

Minimizing reliance on apps by having a separate downloadable app option for users to engage with the product after the cafe.

Being transparent in showing users how the machine processes SCGs into usable products.

early wireframe versions of the home screens and explore page

FINAL DIRECTION

UI/UX Wireflow

Grounds feature a continuous compression molding system that creates pod cups and lids with other natural ingredients, forming the perfect carrier for plant seeds. Its structure supports natural ventilation and guides users throughout the molding process.

When finalizing our machine model, we wanted to make the machine height appropriate for a variety of users. Keeping the trays at the bottom tier allowed the rest of our machine to be more elevated and accessible for users to grab and interact with the machine.

The interface mimics the journey of the SCGs, glowing as the pod molding process progresses throughout the machine.

After the brewing process, spent coffee grounds can be repurposed into new materials, which are especially suitable for low-cost composting as they can biodegrade and release high levels of nutrients, becoming great fertilizer for a user’s plant collection.

These pods are made of mostly spent coffee grounds. Combined with other additives, the pods are able to biodegrade in soil and provide plants around it with nutrients found in spent coffee grounds and improve soil quality. (Oregon State University)

After collecting a seed pod, users can add their chosen plant to a collection via the Grounds app. The app also allows users to explore cafes and nearby machines, redeem rewards, and learn more about SCGs.

← Check out the app prototype here!